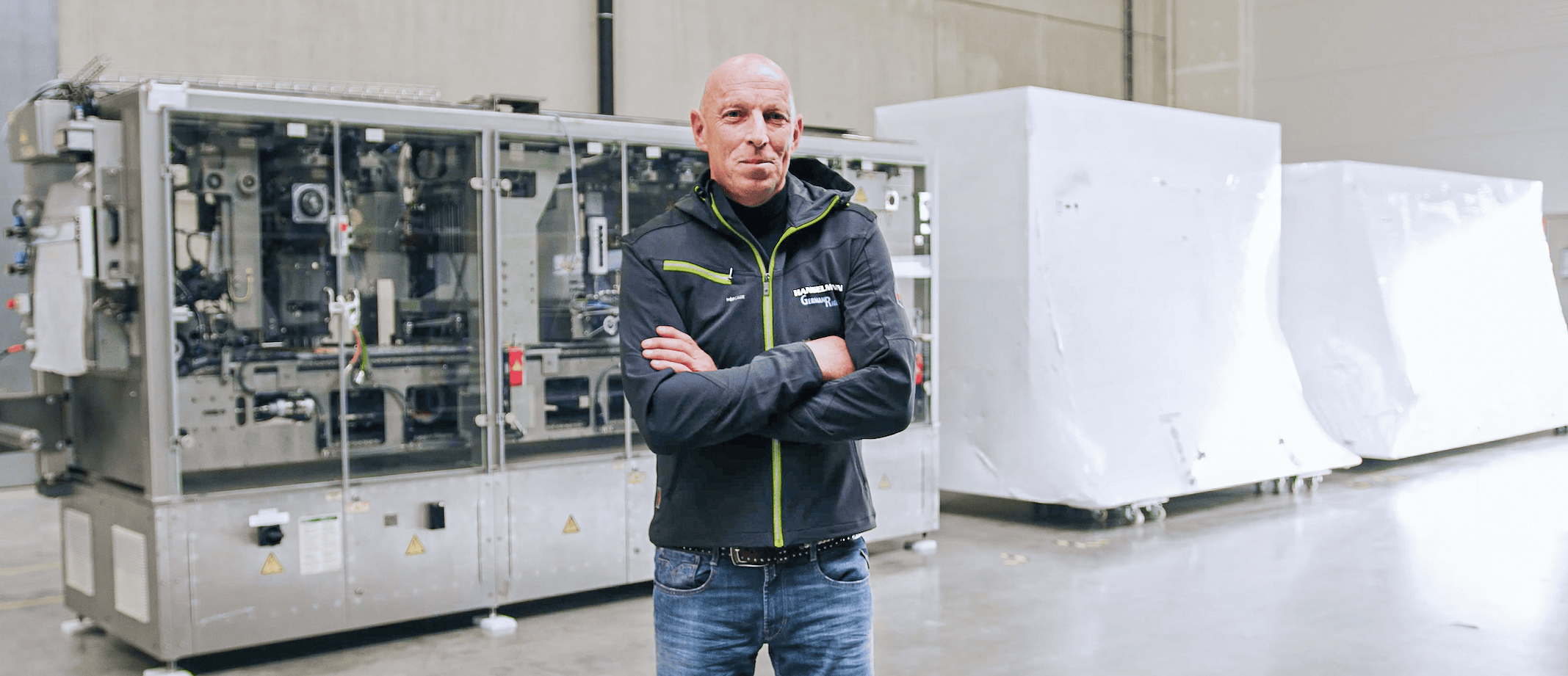

Industrial packaging and machine transport by Hanselmann: innovative logistics 4.0

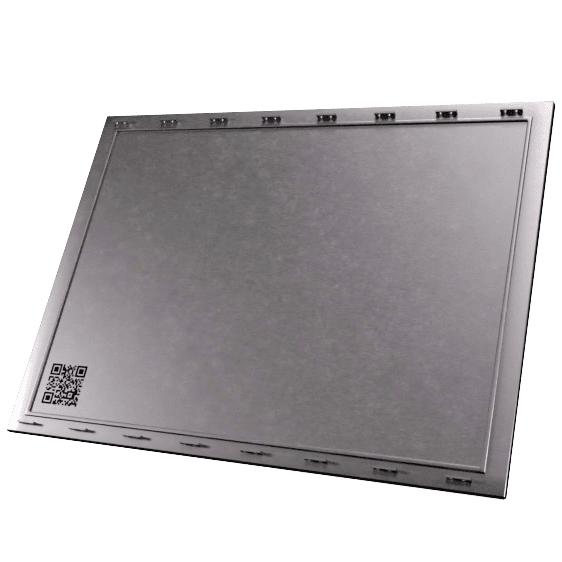

Hanselmann’s new logistics solution , the Holistic Lean Processing System, revolutionizes industrial packaging and machine transport. Developed over the course of 15 years and based on experience from more than 100 projects, this system replaces traditional wooden pallets with an advanced stainless steel baseplate, setting new standards for safe, clean, and efficient machine transport. The baseplate, with a material thickness ranging between 4 – 38 mm, is extremely thin.

Innovative industrial packaging and machine transport with Hanselmann

For more than 50 years, industrial packaging has seen little innovation. Our customers manufacture machines of the highest quality and performance, yet packaging still relies on traditional wooden boxes or pallets. Transport safety falls under the responsibility of the packager.

At Hanselmann, we recognize this issue and offer a groundbreaking, forward-thinking alternative with our Holistic Lean Processing System. This system for industrial packaging replaces conventional wooden pallets with a state-of-the-art stainless steel plate, setting new benchmarks in machine transport. The innovative baseplate not only significantly reduces material usage but also increases transport safety. Thanks to the extremely thin yet robust baseplate, machines can be transported more efficiently and with greater space savings. The system also guarantees improved cleanliness and protection of machines during transport. With over 15 years of development and extensive practical experience, Hanselmann ensures that your valuable machines are optimally protected and transported.

Hanselmann‘s services at a glance

Digital twins for efficient industrial packaging

Hanselmann’s industrial packaging stands out for its flexibility and safety.

It does matter...

- how something is constructed.

- if construction and subsequent packaging lead to oversized or special transports.

- if the designer doesn't consider safe moves and transport of the finished machine.

- whether the packager is responsible for securing expensive machinery.

At Hanselmann, we aim to change this. During the design phase, a digital twin of the baseplate is created, which includes all structural clearances (such as the maximum interior height of a truck, container, or airplane) and all static features and dimensions.

This helps us achieve the following sustainability goals:

Service and contact

Do you have questions?

Your personal contact will be happy to help you.

Customer account

Manage your devices and orders quickly and easily.

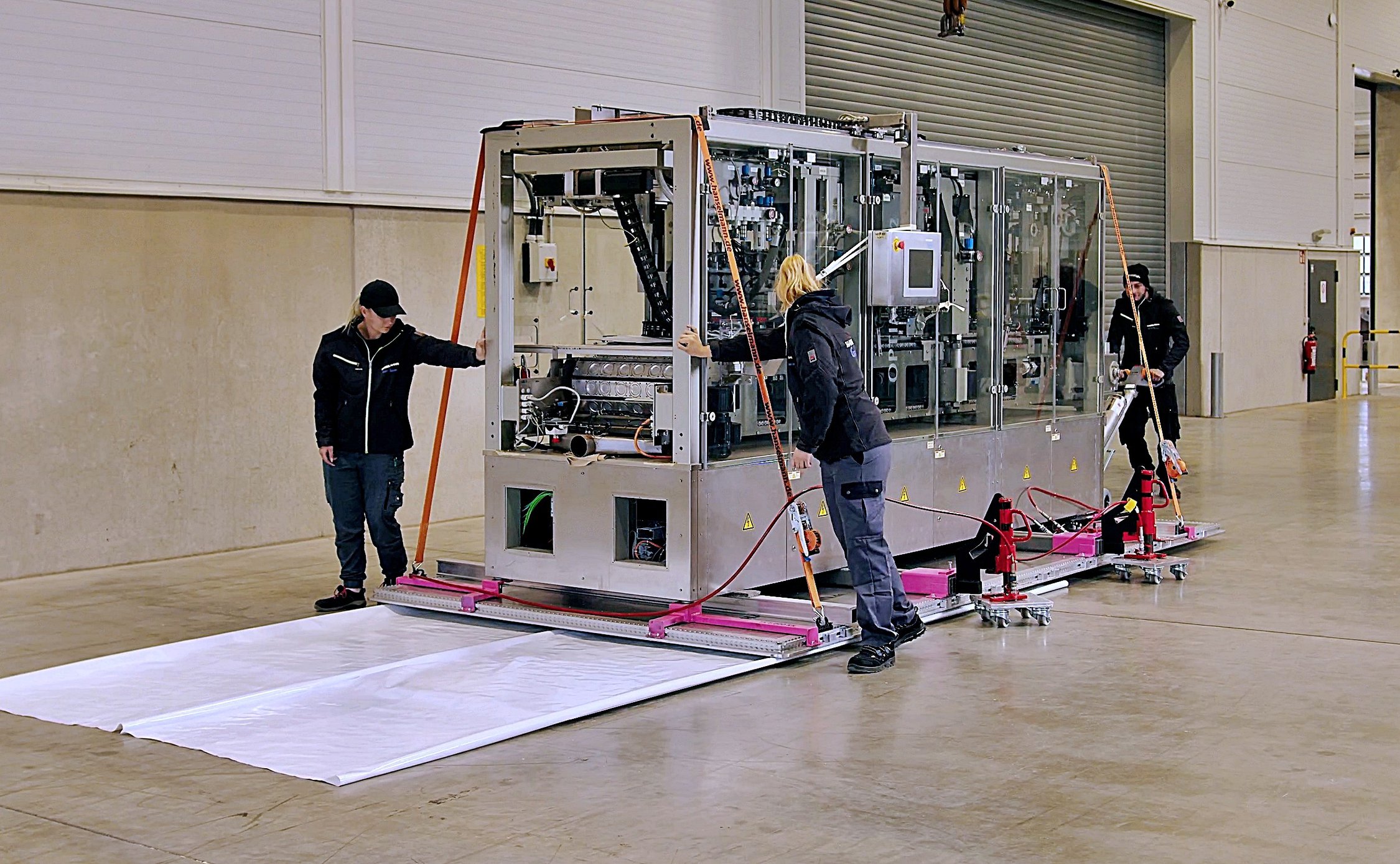

Lift & Roll: standardized processes for quick and safe machine transport

For production and shipping, we offer Hanselmann baseplates in three sizes, available for purchase or as a reusable rental system.

Thanks to the Hanselmann Lift & Roll System, machines can be moved in tight spaces without additional equipment. Within 48 hours, systems can be transported to the next assembly location, significantly increasing efficiency.

Assembly, testing, and other processes are carried out directly on the baseplate, allowing installation at the customer’s site within 72 hours after the FAT.

Flexible logistics solutions with QR code for maximum security

The Holistic Lean Processing System standardizes the entire transport process from the factory to the final destination at the customer’s site. The baseplates are suitable for:

- Truck shipping

- Sea container shipping

- Air freight

An individual QR code on the baseplate ensures seamless tracking of all system parts. A special wrapping protects the machine from dust and environmental influences during transport, whether by truck, sea container, or airplane.

Push & Pull: innovative solutions for smooth delivery

The system also offers standardized unloading with the Push & Pull sliding system, which works flawlessly everywhere, including cleanrooms. Thanks to this new logistics solution, the machine remains clean and perfectly secured during the transport and unloading process, making it ready for immediate use at the final location.

Hanselmann Logistics 4.0 solutions offer significant competitive and sustainability advantages:

- Standardized processes, often combined with logistics or intralogistics contracts

- 25 % less transport weight

- 100 % less wooden packaging

- 30 % less transport volume

- 30 % reduced labor costs

- 50 % increased safety: improved accident protection when moving goods

- Significant reduction of project times

Thanks to innovative logistics solutions and the integration of Hanselmann products, companies can begin production weeks or even months earlier, creating significant competitive advantages.

Showcase: Hanselmann general support in large projects

In recent years, several large projects have demonstrated the following impacts and benefits:

- We can significantly surpass traditional best-case planning.

- The entire project is digitally recorded and displayed using the latest technology and systems.

- We offer just-in-time logistics for all integrated machines and systems.

- We offer visualized and monitored storage.

- Cleaning and pre-assembly services significantly shorten processes.

- Hanselmann cleanliness concepts and products for cleanroom assembly reduce particle contamination by 50-200 kg per integration day.

- ISO 8 machine covers enable assembly and adjustments in unclean working environments.

- A comprehensive insurance concept from takeover to integration protects against unforeseen failures.

- Project management and support teams coordinate all processes from day one to project completion.

- Meeting optimization, meaning required support is immediately provided, and issues are resolved as they arise.

In total, projects utilizing Hanselmann products have been completed weeks or months earlier. For example, one of our customers is able to save approximately 3 million euros of value every day with our logistics solution.

Your contact person

FAQ – frequently asked questions about industrial packaging and machine transport by Hanselmann

Hanselmann’s industrial packaging uses a stainless steel baseplate instead of wooden pallets and packaging. This innovation enables standardized, safe, and clean machine transport, ensuring that transport security is not left to chance. We treat machine packaging, storage, plant assembly, and machine transport as an interconnected process.

With Hanselmann’s systems, logistics are different and better:

- The machine’s designer plans and calculates the transport security measures.

- Up to 40 % of each truckload and 30 % of the transport weight consists of traditional packaging – we eliminate this aspect.

- Unloading and unpacking are no longer improvised affairs.

- High-quality machines are no longer contaminated during the packaging process.

Our goal is to reduce traditional packaging by at least 90 % through our reusable systems, which helps the environment and enhances the quality of the delivered product.

If you prefer to stick with conventional industrial packaging, we can also manage this through a system partner.

Hanselmann’s Holistic Lean Processing System is a comprehensive solution. It is based on a physical baseplate, available for purchase or as a reusable rental system, which securely transports all components and supports the entire process from the design phase to final assembly.

The digital twin of the baseplate is integrated during the planning phase, simplifying and standardizing transport security. All assembly steps and transports occur on the baseplate. Once at the customer’s site, there is no need for unpacking. The only task is to remove the outer membrane, which is soiled during transport. After that, the machine is immediately ready for integration. The system can either remain under the machine or be easily dismantled and returned to us freight-free. Our experts guide you through every step, from planning to final installation, ensuring a smooth process.

The Lift & Roll system enables the transportation of machines at any time and location without the need for additional equipment. It ensures that systems can be moved to the next assembly site within hours or days, depending on requirements, and allows for standardized movement and installation at the customer’s site.

Hanselmann uses a special wrapping and a double plate to protect machines during transport. Security systems for trucks and containers ensure that the systems are always secured and protected. The transport security measures, planned by the machine’s designer, secure the machine to the baseplate. This way, security is not left to the packager but is considered from the very beginning.

Yes, each baseplate is equipped with a unique QR code, which allows for seamless tracking of the system components. This way, you can always stay informed about the transport process.

Thanks to the Holistic Lean Processing System and the Push & Pull sliding system, the machine can be delivered and installed within 72 hours after FAT in an ISO 5 cleanroom standard. If there are no special requirements, machines can be perfectly integrated and positioned within just a few hours.

Hanselmann’s high customer satisfaction rating on Google

Our years of experience and customer-oriented approach ensure that our customers always expect the highest quality and reliability. This is reflected in the many positive Google reviews. See for yourself and become part of our satisfied customer base.