From 2 to 5 April 2025, international scientists and engineers met at the Hanselmann showroom in Crailsheim to present the results of a six-month development project and test them under realistic conditions. The focus was on a newly developed cleaning process for the ITER fusion reactor in Cadarache (France).

Development of a highly specialised cleaning system

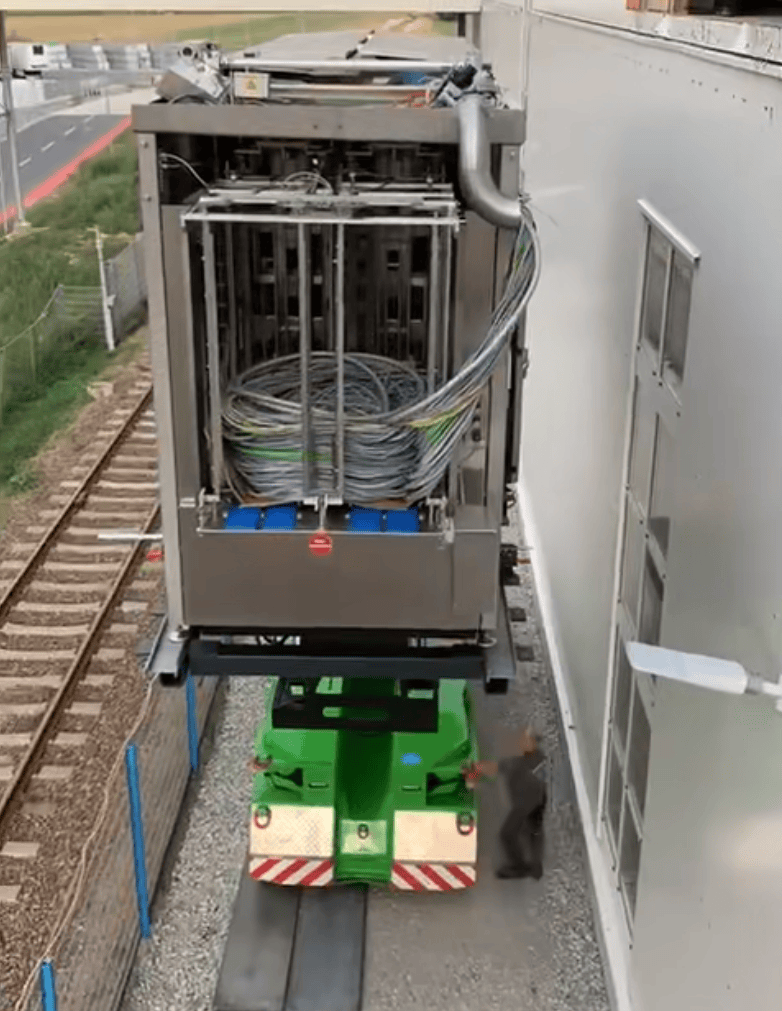

As part of the project, the following components were developed specifically for use in the ITER reactor:

One CO₂ snow jet nozzle For effective cleaning of extremely narrow gaps

A modular handling system for flexible use in technical systems engineering

A customised cleaning process for sensitive surfaces in fusion research

Comprehensive technical documentation

An operator model for later use in the real world

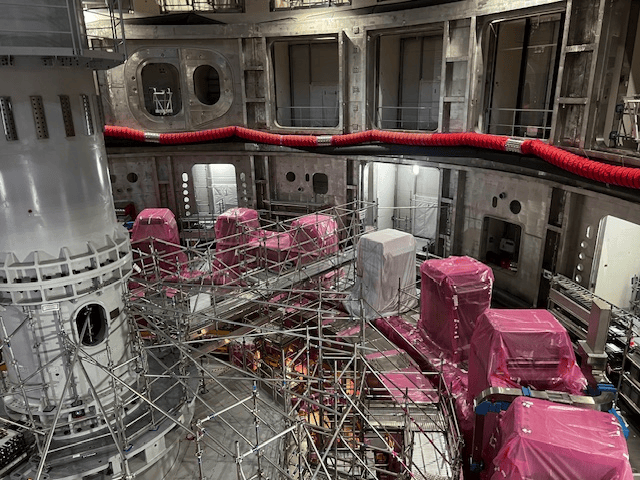

These components were fully integrated into the network Hanselmann cleaning technology and manufactured as Mockup model provided.

Real conditions for realistic tests

For the test series, test surfaces were contaminated with typical particles exactly according to the ITER specifications. These contaminated surfaces were built into the mock-up model in order to create a realistic Test setup for CO₂ snow jet cleaning to create.

The test cleaning was carried out under strictly controlled conditions. The aim was to simulate the cleaning process as realistically as possible - including the tight structural conditions in the fusion reactor.

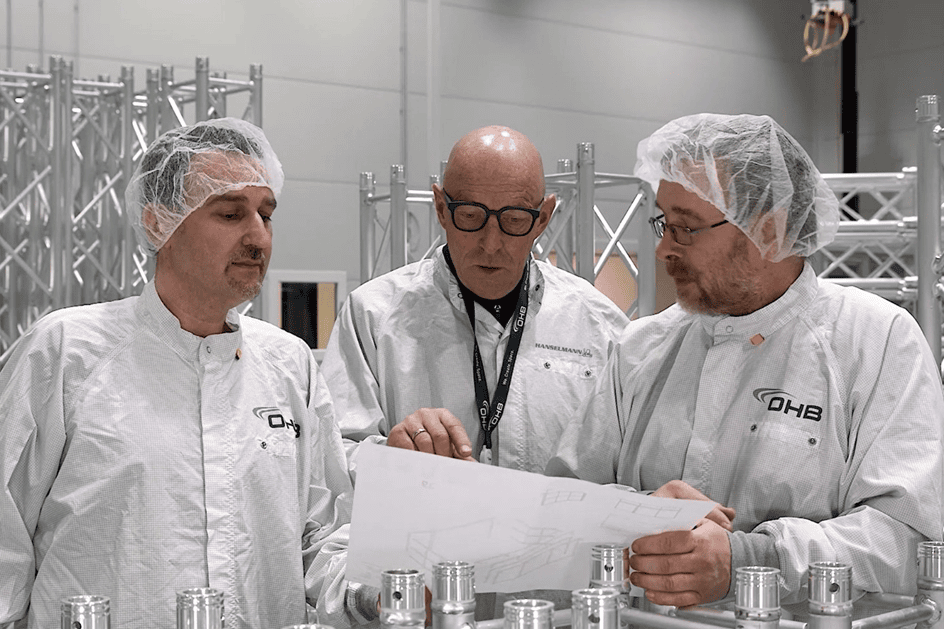

High-calibre participation from research and industry

Renowned representatives from science and industry took part in the demonstration trial:

Dr Axel Müller - OHB

Friedrich Hanselmann - CEO Hanselmann

David McKeown - Assistant Professor at the University College Dublin (UCD)

Christian Penzkofer & Benedikt Dillmann - OHB

Rebekka Rössel - Dastex

Felix Teichert - Hanselmann

Carsten Moschner - Former CEO Dastex, now consultant

Stefan Merkle - CEO Merkle Solutions

Christophe Jarrige - ITER Project Manager

The team of the UCD Dublin arrived on 2 April under the direction of David McKeown. The entire trial was prepared and supervised by the Hanselmann team.

Successful conclusion and follow-up order

The cleaning was completed on 4 April 2025 - all data was collected and evaluated. The results were consistently positive: the newly developed CO₂ purification process for the ITER fusion reactor proved to be technically feasible and efficient.

Based on these results, Hanselmann was immediately entrusted with a follow-up order: Two particularly critical components in ITER are to be cleaned by mid-June 2025. This cleaning is a prerequisite for the planned First switch-on of the ITER experimental reactor.

Outlook: Innovation from Crailsheim for the energy of tomorrow

The project impressively demonstrates how German engineering skills, international research and practice-orientated implementation can go hand in hand. With its contribution to the fine cleaning of technical components in the ITER fusion reactor, Hanselmann is making an important contribution to the future of sustainable energy generation.