Project group realises ambitious satellite project Cleanroom T 319

OHB System AG is one of Europe's leading space technology companies. The systems provider is part of the listed high-tech group OHB SE, in which more than 3,000 highly qualified employees work primarily on central European space programmes. The Oberpfaffenhofen site covers the fields of optics, science and robotics.

OHB is currently realising the ESA PLATO mission. A new concept of a 4 x 4 x 3 m³ space telescope, which will use a total of 26 individual cameras to search for and characterise Earth-like planets in our Milky Way from 2026.

A consortium consisting of OHB, C3, QleanAir, Hanselmann, Dastex, Merkle, Panterra and Dorfner took up the challenge of meeting the required 16 x 10 x 6 m³ ISO5 Clean room within a 5 days window between the completion of construction and the start of integration.

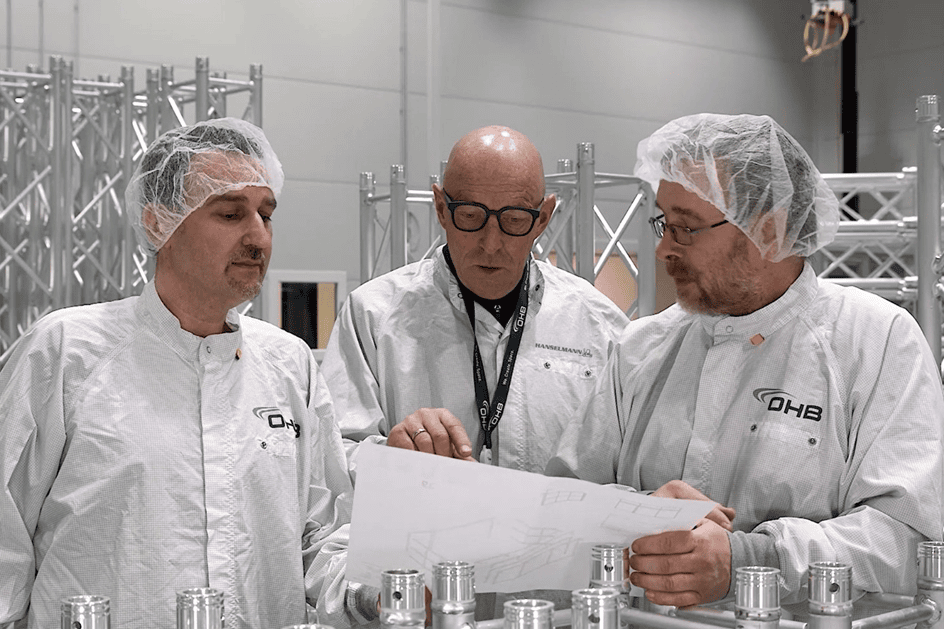

Such projects require an experienced team with an impressive track record. The project managers at OHB took a different approach: they had a perfect plan for what they wanted to build and optimised the function and visualisation.

Dr Axel Müller and Friedrich Hanselmann, CEO of Hanselmann GmbH, know that mutual trust, loyalty and maximum commitment are the basis for successful cooperation.

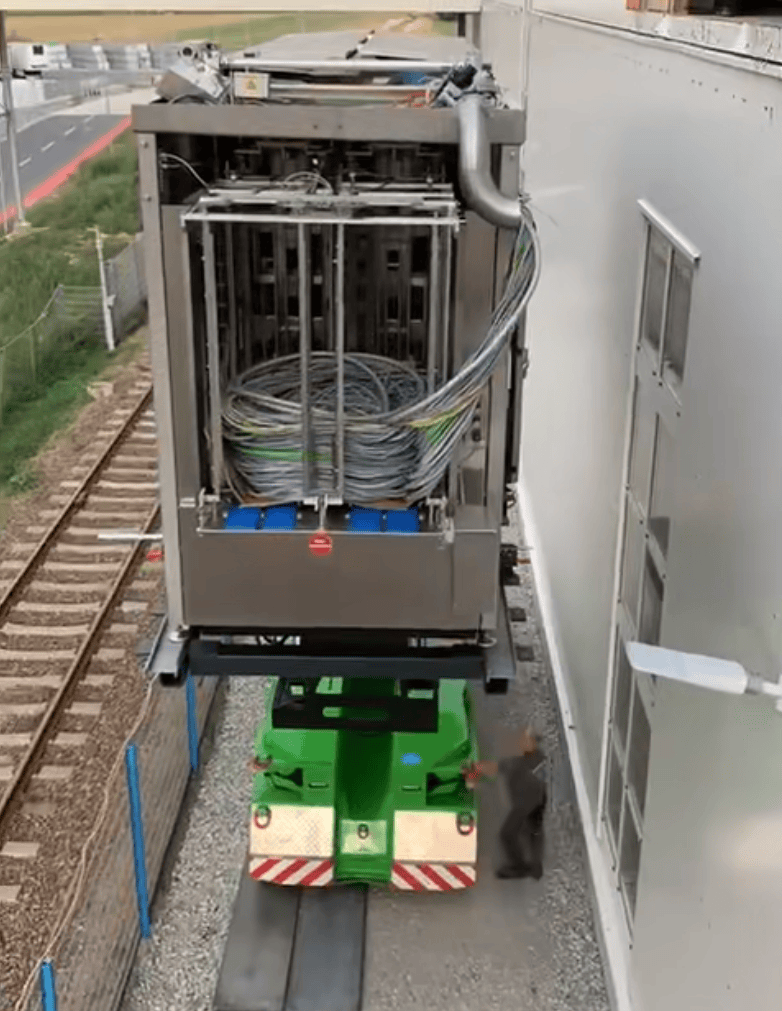

Hanselmann GmbH received the general enquiry for construction, technical design, procurement, logistics, pre-assembly and integration in accordance with defined cleanliness requirements.

We were able to fulfil the trust placed in us: In only 5 installation days, without significant reworking, the Cleanroom T-319 finally installed. Another new feature was the live broadcast of the entire installation. The resulting uncut Time-lapse video is revolutionary and demonstrates the high quality of the design in a unique way.

Friedrich Hanselmann, CEO of Hanselmann GmbH, describes the development of the in-house pharmaceutical industry department as follows:

"Thanks to high-end integrations for the optical industry, chip production and pharmaceutical companies in Europe and North America, Hanselmann's industrial division also established itself internationally last year. The successes in shortening projects using the Hanselmann system "Bestcase Minus X" or "Holistic Lean Processing System" are particularly outstanding.

Hanselmann GmbH shortens complex projects in the pharmaceutical and chip industry by weeks and months through the use of cleanliness products and special logistical solutions. This efficiency and innovative strength are just some of the company's unique selling points."

In this project, OHB and Hanselmann show that trust and an innovative mindset lead all parties involved to sustainable and efficient success. The follow-up project is already in the starting blocks and Hanselmann GmbH is looking forward to continuing and expanding the partnership.