Hanselmann cleanroom assembly: ISO 5 cleanroom revolution

In the highly sensitive fields of aerospace engineering and the pharmaceutical industry, cleanliness and precision are essential. Traditional manufacturing processes often reach their limits, especially when it comes to cleanroom assembly and cleanroom technology. These requirements have inspired us at Hanselmann to develop the Holistic Lean Processing System – an innovation that has already attracted the attention of leading companies.

Learn more about our proprietary system!

Our innovative Holistic Lean Processing System: new cleanroom technology for the highest cleanliness standards

Hanselmann’s Holistic Lean Processing System revolutionizes the way machines and equipment are manufactured, packaged, and delivered. By implementing strict cleanliness requirements, for example in cleanroom ISO 8 or higher environments, we ensure that your machines are optimally protected throughout the entire production process. This is particularly important for cleanroom production in the pharmaceutical industry, the optics industry, and aerospace.

What is a cleanroom?

A cleanroom, also known as a “clean room”, is a controlled environment where the concentration of airborne particles, germs, and other contaminants is minimized. Cleanrooms are commonly used in the pharmaceutical industry, semiconductor manufacturing, and other highly sensitive industries where an extremely clean environment is essential to ensure the quality and safety of products. Conditions in a cleanroom, such as humidity, temperature, and air pressure, are precisely monitored and regulated to meet stringent standards.

The solution for special cleanroom ISO 5 requirements

A key aspect of our system is the provision of temporary cleanrooms that enable machines and equipment to be produced under the highest cleanliness standards. Unlike many other manufacturers who build their machines in uncontrolled environments, we focus on clean production. By doing this, we can drastically reduce particle counts and speed up the integration, the validation process, and the production time.

Holistic Lean Processing System

Our Holistic Lean Processing System is the solution for efficient cleanroom logistics. Through optimized cleanroom production and specialized transport methods, we make sure that all components and materials reach the cleanroom under controlled conditions. This prevents contamination even before the cleanroom assembly begins. Our expertise in cleanroom logistics and assembly allows us to meet even the most demanding Cleanroom ISO 5 requirements, providing the highest quality in production.

Hanselmann‘s services at a glance

Cleaning, industrial packaging, transport and integration of machines under cleanliness requirements corresponding to cleanroom classes ISO 8, ISO 7, ISO 6, or ISO 5

Provision of temporary cleanrooms for the production of machines and equipment

Provision of digital twins in design to optimize transport security and processes

Provision of our innovative physical baseplate systems for efficient machine and equipment setup and transport

Provision of cleanliness products during the integration of machines and equipment

You’ll find more information about our Holistic Lean Processing System in our industrial packaging section.

Cleanroom modular systems and cleanroom technology at the highest level

Cleanroom requirements, whether in pharmaceutical cleanroom production or cleanroom medical technology, are highly specific. Cleanroom ISO 5 criteria, for example, require an extremely low particle count, which is not achievable in many traditional production facilities. Our 3C network has developed a temporary performance cleanroom system tailored to our customers' needs.

At Hanselmann, we take responsibility for the logistical optimization of your products so that the cleanliness requirements for cleanrooms are fully met. This includes the development of a modular system. This is implemented by us with the latest Clean room measurement technology monitored to ensure that the cleanroom ISO 5 Cleanliness is guaranteed at all times.

Advantages of modern cleanroom technologies

With our simple yet efficient modular system, we can create a fully operational ISO 5 cleanroom in the shortest time possible. The system can be built in various sizes, depending on the requirements.

At the beginning of the project, we need the following information:

- Which process do you want to perform under cleanliness requirements?

- What are the conditions of your premises?

Based on this information, we will create a cleanroom concept within a maximum of eight weeks and simulate the application. This will determine the requirements and the composition of our modular system. The cleanroom setup then usually takes four weeks.

The modular system can be upgraded with special ESD-compliant flooring or heavy weight upgrades. This allows us to remain flexible in our cleanroom setup and meet ISO 5 cleanliness requirements for large projects.

The largest system to date measures 18 x 10 meters. The usable cleanroom area is 250 square meters.

Pre-cleaning and packaging at our Crailsheim location

At our headquarters in Crailsheim, we clean and package spare parts, machines, and equipment upon request for upcoming integrations into customer cleanrooms.

We provide cleanliness products for maintenance and repairs to perform the process in isolation. Both users and machine builders benefit, as the cleanroom is ready for use earlier, which helps to optimize the customer service and reduces costs.

Pre-cleaning and packaging at our Crailsheim location

At our headquarters in Crailsheim, we clean and package spare parts, machines, and equipment upon request for upcoming integrations into customer cleanrooms.

We provide cleanliness products for maintenance and repairs to perform the process in isolation. Both users and machine builders benefit, as the cleanroom is ready for use earlier, which helps to optimize the customer service and reduces costs.

Advantages of modern cleanroom technologies

By using the latest cleanroom technologies, we shorten our customers' project times and validation processes by weeks or even months. This not only leads to significant cost savings and dust reduction, but also greatly improves the quality of delivered and installed products and production processes.

Thanks to our advanced cleanroom technology, we can guarantee the highest quality standards and ensure that your products meet the strict requirements of cleanroom classes.

Contact Hanselmann for your cleanroom solution

If you want to learn more about our innovative cleanroom solutions, Hanselmann is always available to assist you. As the leading provider of cleanroom assembly and production, we offer customized solutions tailored to your specific requirements. Our expertise in cleanroom technology, combined with our experience in ISO-certified cleanrooms, allows us to complete projects quickly, efficiently, and to the highest cleanliness standards. Contact us today to find out how we can optimize your production process and successfully implement your cleanroom projects.

Cleanroom planning: tailored services for the implementation of your cleanroom projects

With our simple yet efficient modular system, we can create a fully operational ISO 5 cleanroom in the shortest time possible. The system can be built in various sizes, depending on the requirements.

At the beginning of the project, we need the following information:

- Which process do you want to perform under cleanliness requirements?

- What are the conditions of your premises?

Based on this information, we will create a cleanroom concept within a maximum of eight weeks and simulate the application. This will determine the requirements and the composition of our modular system. The cleanroom setup then usually takes four weeks.

The modular system can be upgraded with special ESD-compliant flooring or heavy weight upgrades. This allows us to remain flexible in our cleanroom setup and meet ISO 5 cleanliness requirements for large projects.

The largest system to date measures 18 x 10 meters. The usable cleanroom area is 250 square meters.

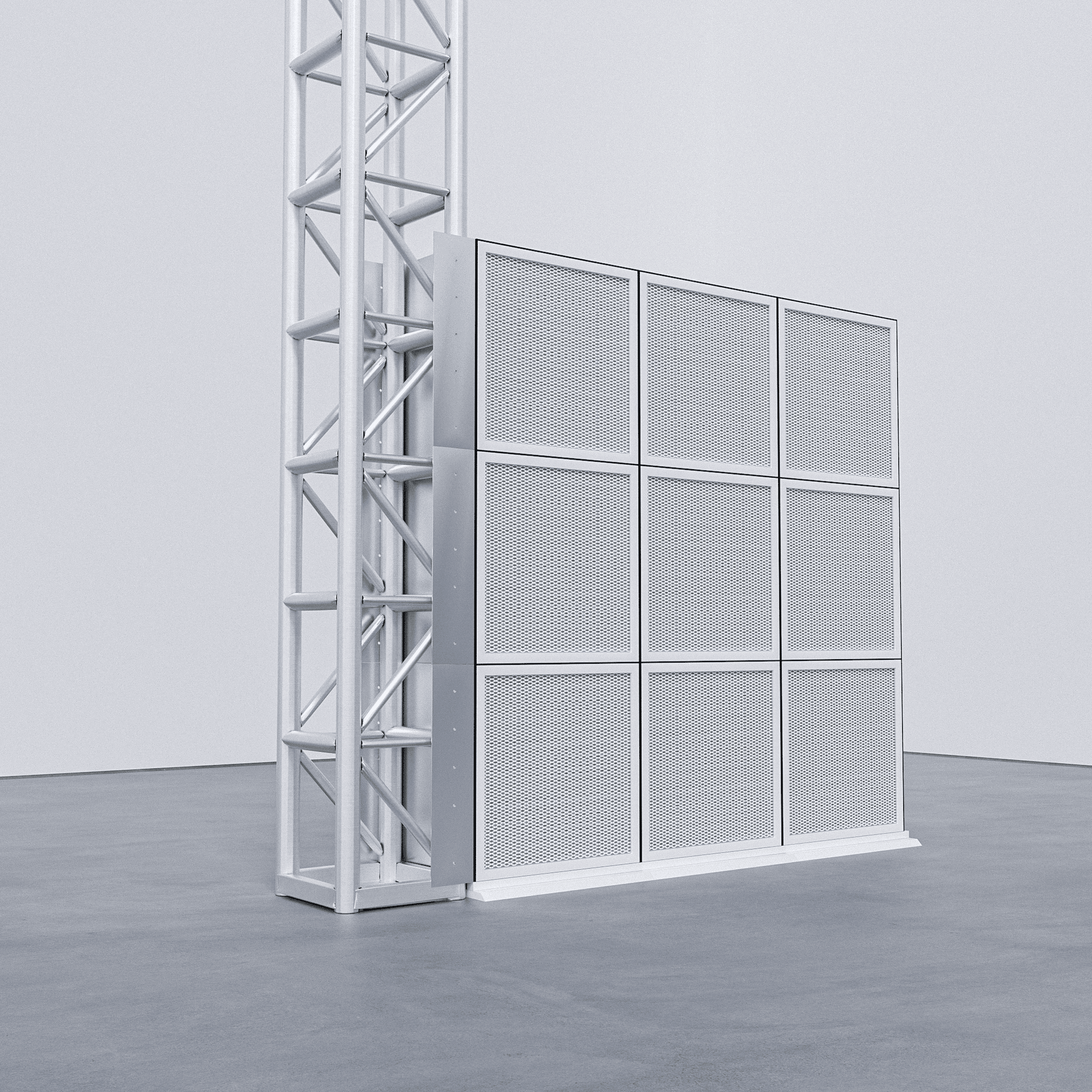

360° panorama test setup of a clean room

The shown ProTECT cleanroom system measures 18,000 mm width, 10,000 mm height and offers a Usable floor space of approx. 220 m². It not only fulfils the requirements for ISO 5, but clearly surpasses them:

During the acceptance Almost no particles measured in the system.

The system is based on 16 FFU wall modules from Hanselmann, individually with Filters and fans can be fitted. The Modular system is flexibly scalable - almost unlimited in length, the current Overall height is approx. 10,000 mm.

Your advantages:

Cleanroom class ISO 5

Modular and flexible expandable

Customised equipment with FFU technology

220 m² usable area realisable

Your contact person

FAQ: Cleanroom Assembly

Production in cleanrooms protects machines and equipment from particle contamination. This is crucial, as machine building processes can take several months, and certain areas cannot be cleaned after assembly. These include hard-to-reach areas and crevices as well as sensitive surfaces. By adhering to cleanliness requirements, we ensure the quality of products, especially in sensitive industries like the pharmaceutical and aerospace sectors.

At Hanselmann, we offer production capabilities in various cleanroom classes: ISO 8, ISO 7, ISO 6, and ISO 5. These classes guarantee extremely low particle counts, which are especially required in the pharmaceutical, medical technology, and aerospace industries.

Unlike many other manufacturers that produce their machines in uncontrolled environments, we use temporary cleanroom systems specifically tailored to our customers' needs. These systems ensure continuous adherence to cleanliness requirements throughout the production process. We refer to our system as a performance system: as soon as a particle is released, air molecules transport it to the filter medium where it is captured.

By using our cleanroom technology and the Holistic Lean Processing System, project timelines and validation processes can be shortened significantly. This results in cost reductions and enables the machines and equipment to be operational weeks or even months earlier.

Hanselmann’s high customer satisfaction rating on Google

Our years of experience and customer-oriented approach ensure that our customers always expect the highest quality and reliability. This is reflected in the many positive Google reviews. See for yourself and become part of our satisfied customer base.